We only ship in the US

FREE SHIPPING

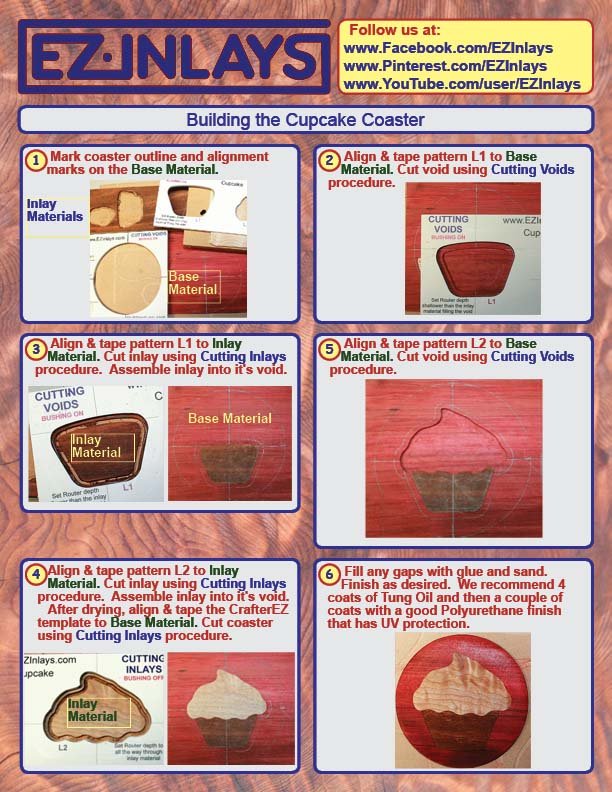

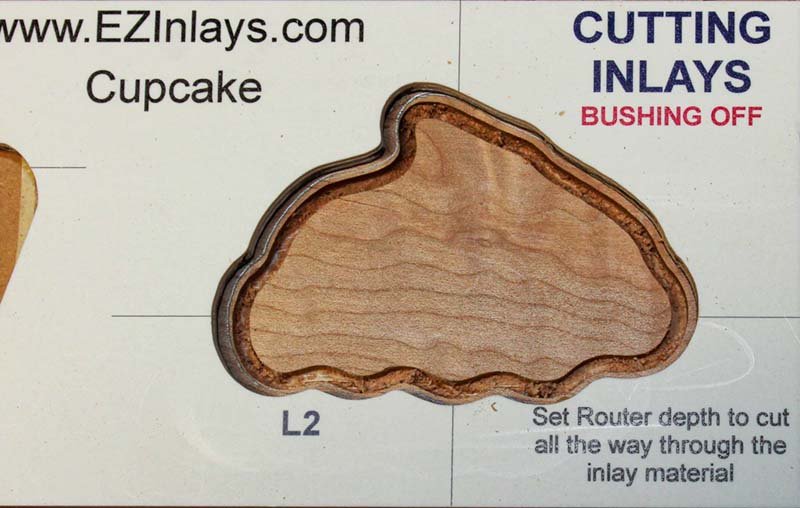

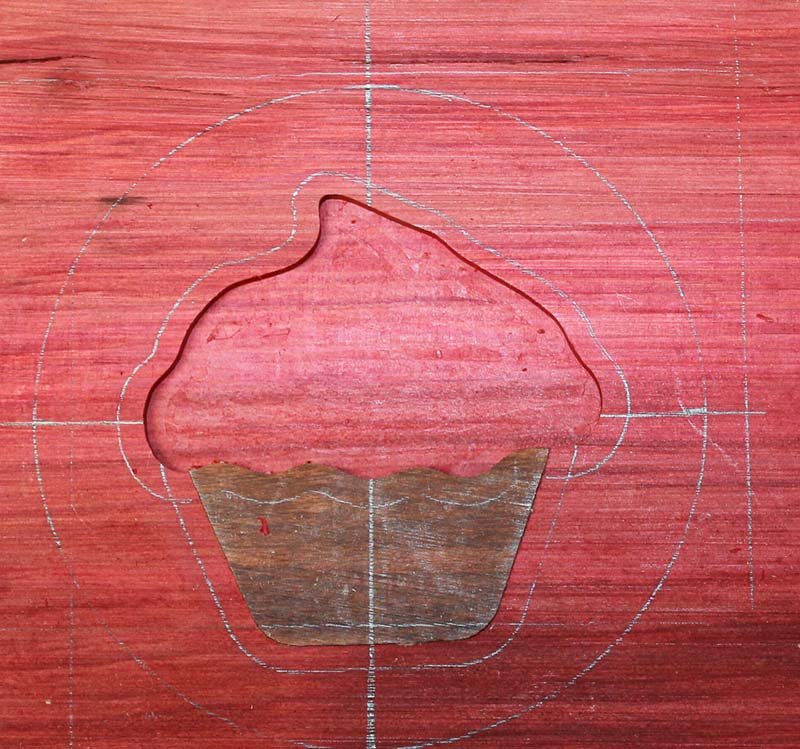

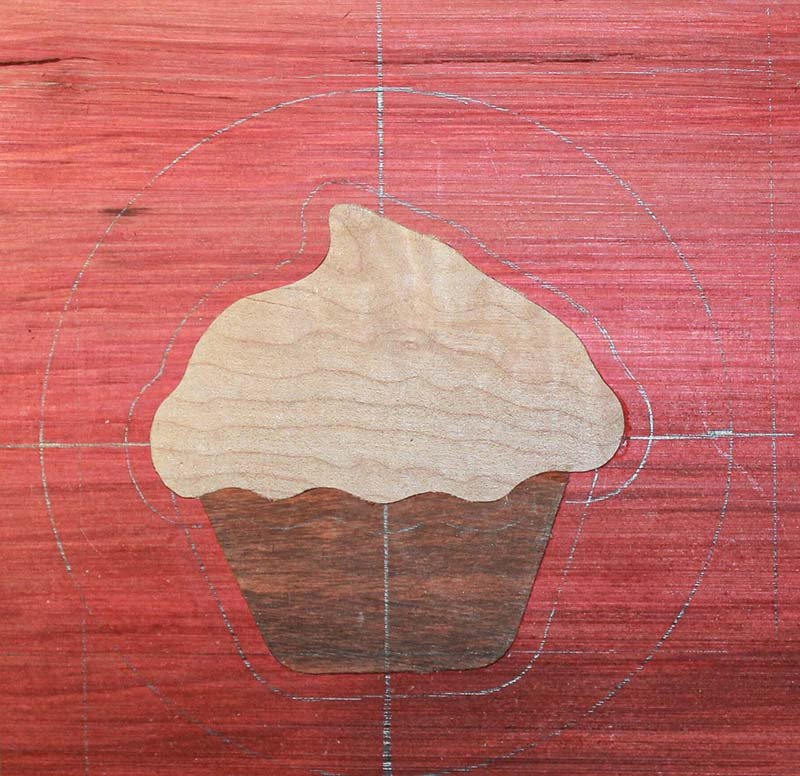

For $15 you'll receive the Cupcake inlay template that can be used to add a cupcake to your project or be placed in the center of a coaster. When building a coaster the Cupcake template is used with the Crafters kit. If you already have a Crafters kit great! If not it can be purchased for $25.

It takes about an hour to build the Cupcake inlay, even less if you're inlaying it into something other than coaster.

This is one of the simplest inlays you'll ever build. Be warned though, there's a real chance you might want a snack after building this inlay! :O

To build this inlay all you need is some wood and a few basic tools. Click here review the Router Based Inlay Tool List.

Never built an inlay before? Click here to Learn How To Build Any Wood Inlay.