Select the Inlay Materials

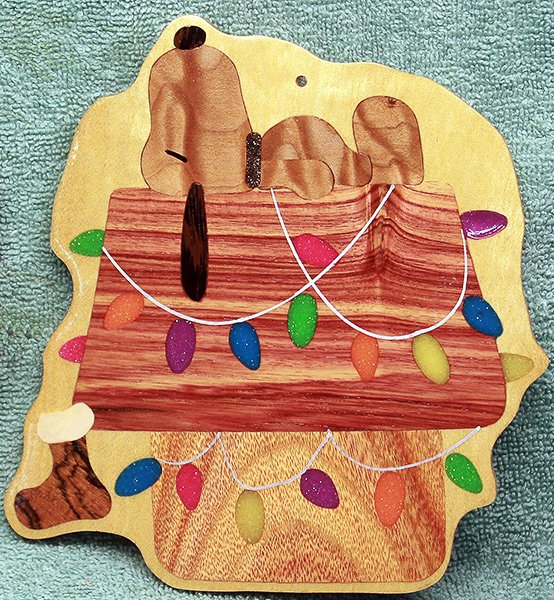

This video explains the process used to select the inlay materials for this build of the decorative inlay Dog Daze Christmas Ornament.

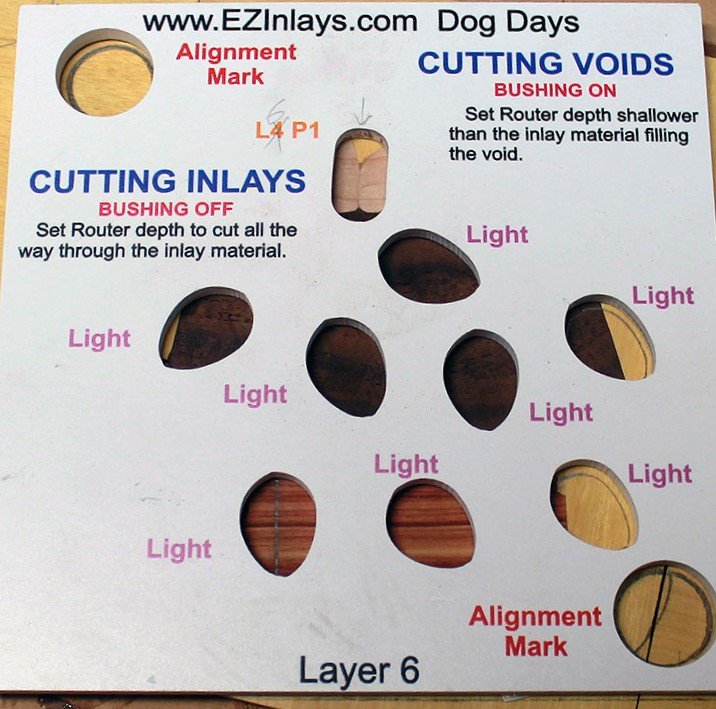

When selecting the inlay materials for Dog Daze you'll want to focus on contrast between the dog, his house, and the background material.

This design was created to honor childhood memories of the Charllie Brown Christmas special. Childhood memories are just the best! :)

INLAY MATERIALS THIS BUILD

* Walnut 7" x 7" x 5/8" - Base material

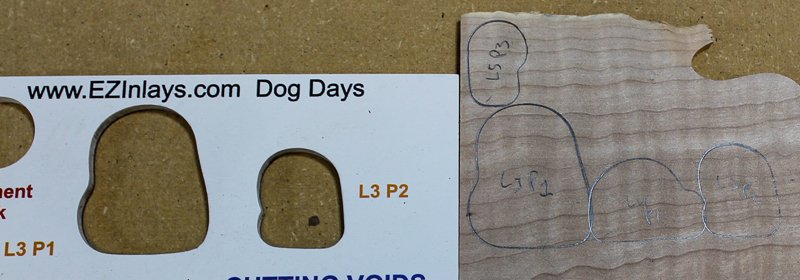

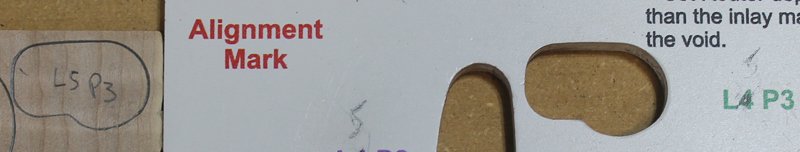

* Quilted Maple 4" x 3" x 1/8" - Dogs body and arm

* Yellow Heart 3" x 3" x 1/8" - Christmas stocking

* Birds Eye Maple 3" x 3" x 1/8" - Fur on the stocking

* Wenge 3" x 3" x 1/8" - Ear and nose

* Rosewood 4" x 3" x 1/8" - Bottom of dog house

* Bacote 6" x 3" x 1/8" - Top of dog hose

GENERAL GUIDELNES

When selecting the pieces for the dog try to get the grain patterns between the head, body, and feet aligned. Then for the arm use the same color wood but have the grain direction different than the

rest of the dogs body.

You get to decide what type of material to use for the dogs . Personally I recommend using epoxy and glitter because you can make a "sparkley" for the dog. Dogs love bling! :)

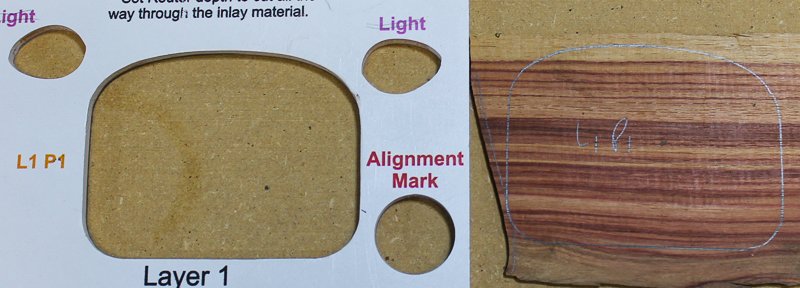

For the roof a horizontal grain patterns seems to provide better contrast between the dog and the roof than a vertical one does.

$75

$75