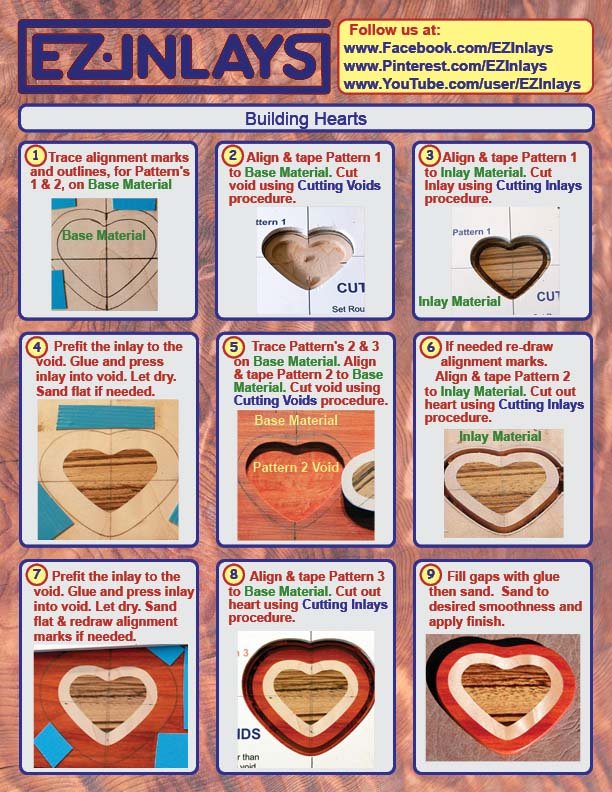

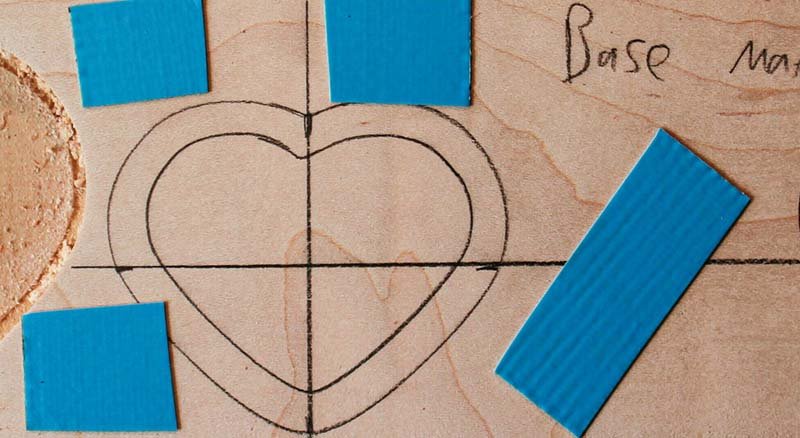

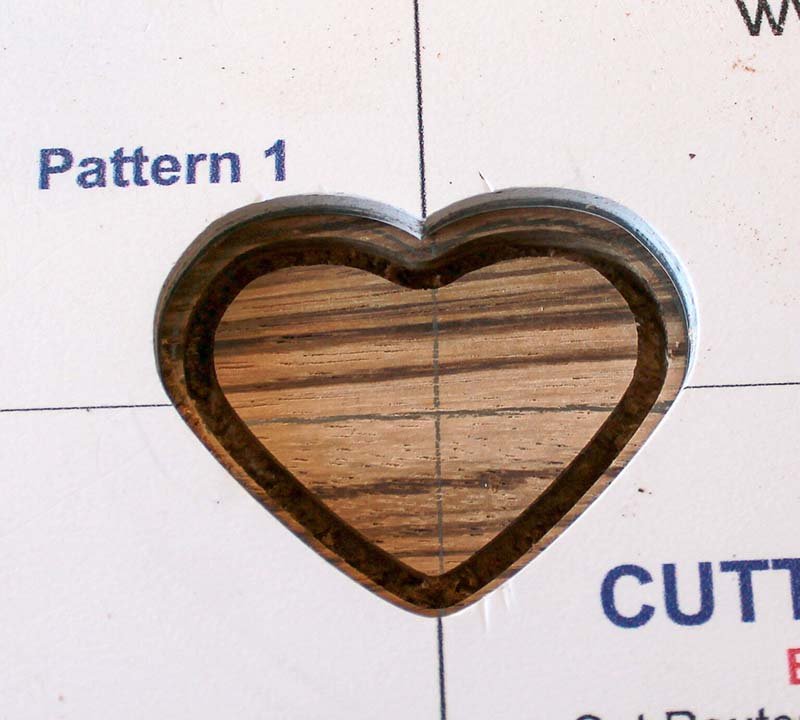

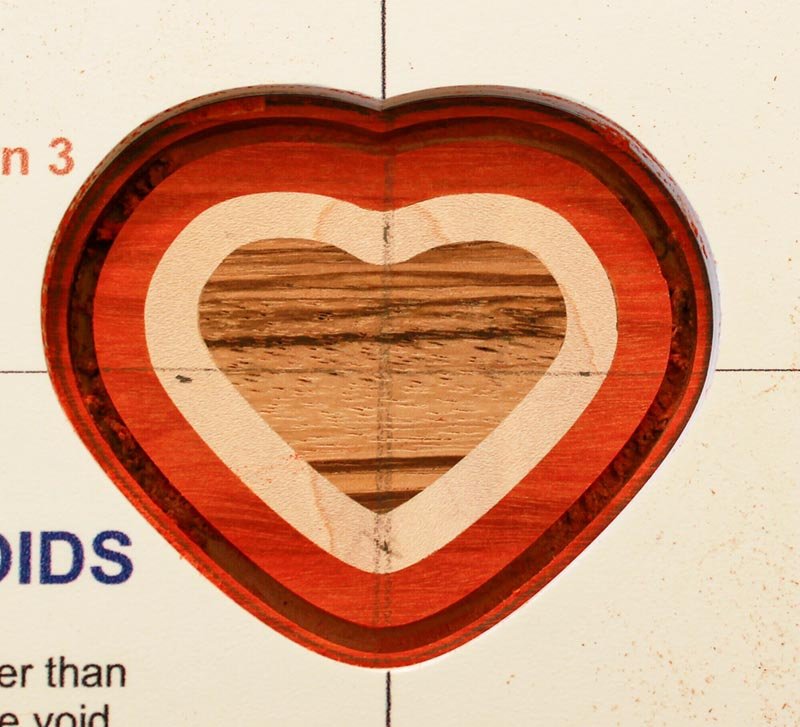

At $20 + FREE SHIPPING, the HeartEZ template is perfect for a low cost introduction to router based inlays. While building an inlaid heart you'll practice cutting sharp points, gentle curves, flat spots, and corners. These are all the cuts you'll ever need to make for any router based inlay.

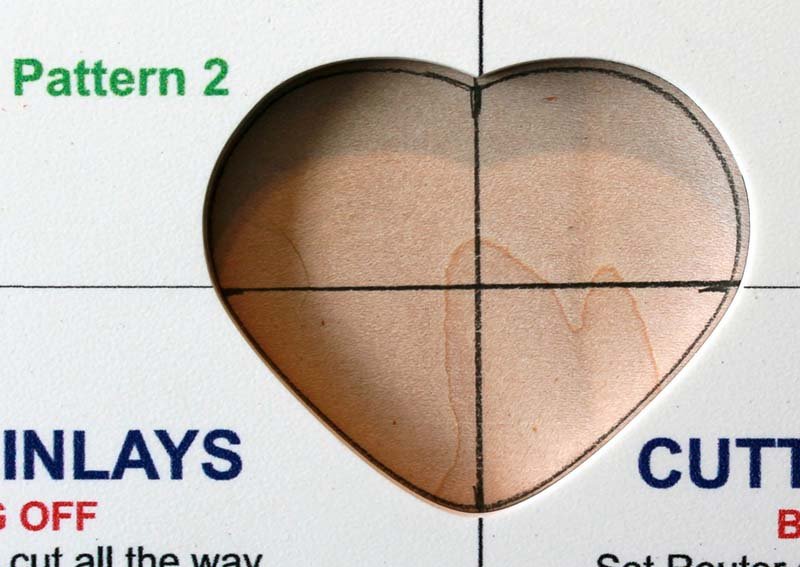

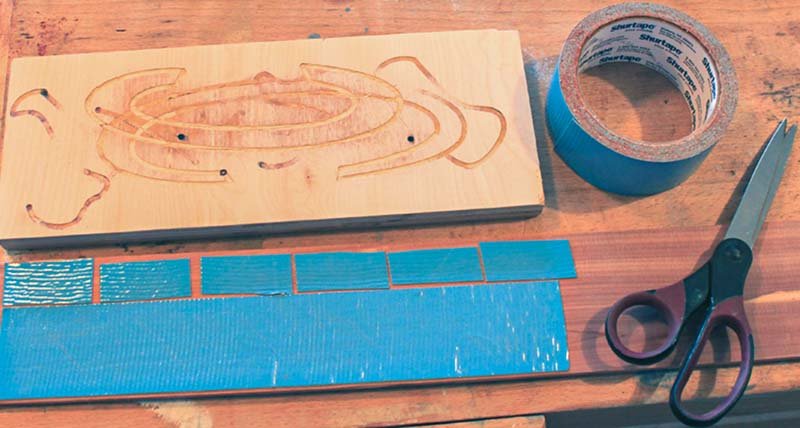

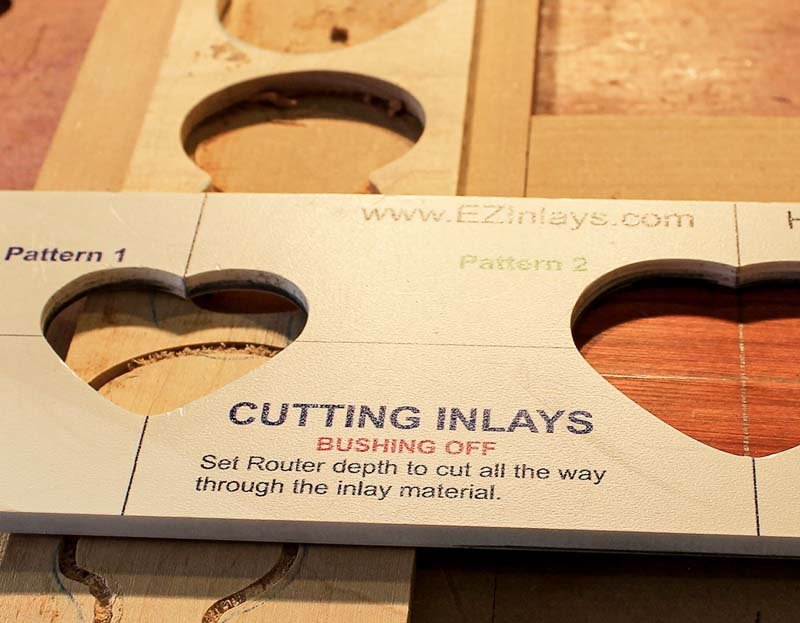

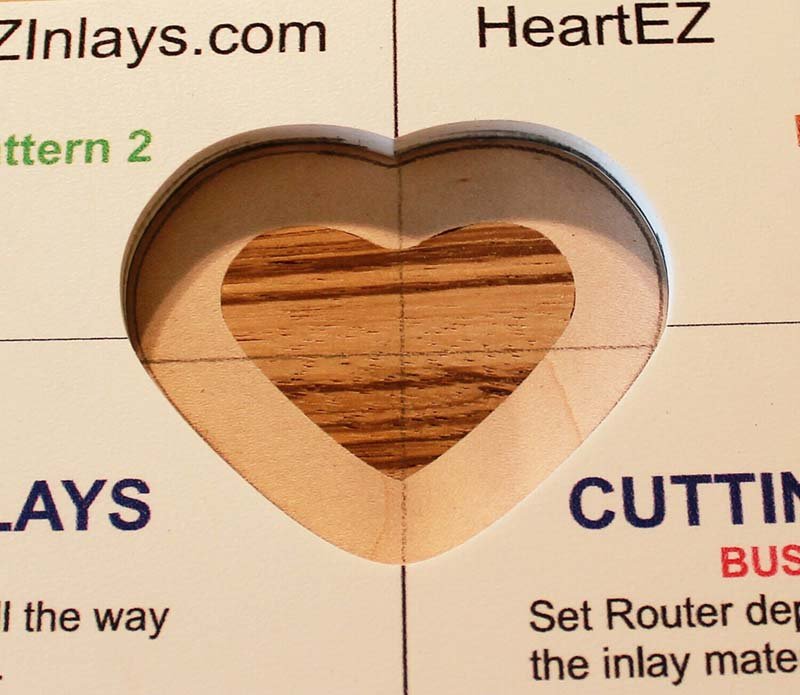

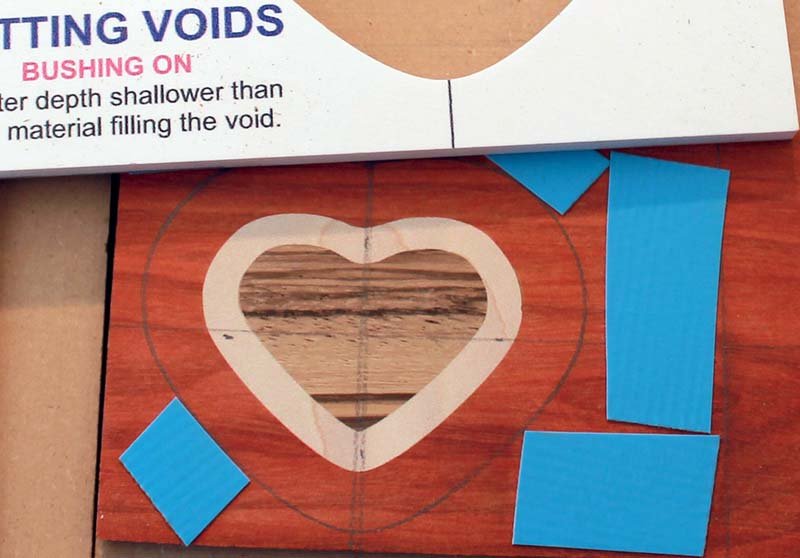

It takes about an hour to build the heart and at the end of the process you'll have cut two "voids", three "inlays" and assembled them into a great gift for that special someone! Between this video and the How to Build an Inlay Tutorial you'll be able to master all the techniques required to build any router based inlay.

Best of all the only power tool needed is a plunge router equipped with a brass inlay kit. There isn't a safer, easier, or more precise way of building inlays. If you follow these procedures you're guaranteed to build flawless inlays quickly, easily, and repetitively!